WE FIX BAD CONCRETE SINCE 1981

Roger Hildebrand established this company in 1981 and takes pride in the ability to supply and install the very best and safest resinous flooring materials in the world. With more than 40 +years as leaders in this industry, we are committed to ensuring that resinous flooring specifications are accurate, up to date and in the client’s best interest for long-term performance.

Our Mission is to provide high performance, top tier quality flooring solutions across Canada, United States and México.

Epoxy Solutions TM provides high quality, epoxy, terrazzo and polished concrete floor systems. We employ only highly skilled tradesmen with extensive training and experience to ensure that our client’s floors look amazing and perform beyond expectation. Our broad experience and continuous education save our customers millions of dollars in costs by accurately specifying the correct solution for your unique environment.

The most important for thing for Epoxy Solutions TM is you!

We use the most environmentally safe products because the human cost is the highest cost. We all breathe the same air and drink the same water and so environment and safety concerns are a top priority.

Epoxy Solutions TM identifies that every concrete surface is subject to unique operating and environmental conditions. We collaborate, with you the client, to gather all the necessary information and then combine that with our extensive years of experience to provide you with the best ‘tailor made’ solution for all your unique needs.

Garage Floor

Repair your garage floor with our epoxy moisture reduction system or concrete capping.

Patios Walkways

We’ll restore the surface of your concrete patio to “like new” or give it a brand new appearance.

Pools

We specialize in cleaning and re-coating new and existing pools for residential and commercial customers.

Interior Finishing

A beautiful alternative to carpet or tile, our epoxy coatings are ideal for loft and basements.

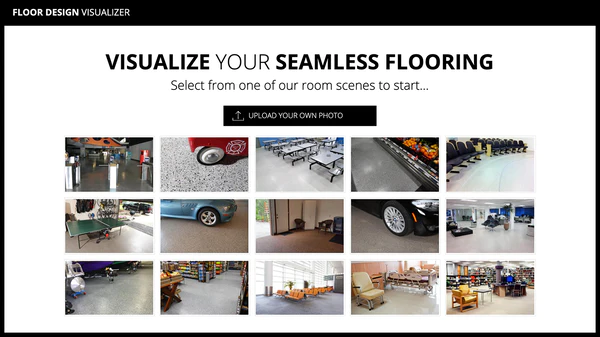

Drag the Slider to See the Transformation One of the Interior